FAV is the Manufacturer of Super Duplex Check Valve Compression, Needle Valve, Ball Valves, Check Valves, Manifold Block & Bleed Valves.

Duplex stainless steels are becoming more common. Duplex Check Valve OD, are being offered by all the major stainless steel mills for a number of reasons:

Higher strength leading to weight saving

Greater corrosion resistance particularly stress corrosion cracking

Better price stability

Lower price

Properties

The combination of chromium, molybdenum and nitrogen convey the good resistance of 2205 to chloride pitting and crevice corrosion. This resistance is extremely important for services such as marine environments, brackish water, bleaching operations, closed loop water systems and some food processing applications. The high chromium, molybdenum and nitrogen contents of 2205 provide corrosion resistance superior to common stainless steels, such as, 316L and 317L in most environments.

Advantages

The advantage of a Super Duplex Check Valve OD, is that it combines the favourable qualities of a ferritic alloy (stress corrosion cracking resistance and high strength) with those of an austenitic alloy (ease of fabrication and corrosion resistance).

2205 duplex stainless steel is a cost effective solution for many applications where the 300 series stainless steels are susceptible to chloride stress corrosion cracking. Stress corrosion cracking occurs when stainless steels are subjected to tensile stress, while in contact with solutions containing chlorides. Increasing temperatures also increase the susceptibility of stainless steels to stress corrosion cracking.

| END CONNECTIONS | PRESSURE RATING 100°F (37°C) PSIG | DIMENSIONS MM | Cv | |||

| INLET / OUT LET | L | A/F | ||||

| FAVCV/DF/02/DU | Double Ferrule | 1/8″ | 6000 | 55 | 19 | 0.78 |

| FAVCV/DF/04/DU | 1/4″ | 6000 | 58 | 22 | 1.31 | |

| FAVCV/DF/06/DU | 3/8″ | 6000 | 58 | 25 | 1.52 | |

| FAVCV/DF/08/DU | 1/2″ | 6000 | 65 | 27 | 1.68 | |

| FAVCV/DF/12/DU | 3/4″ | 6000 | 70 | 36 | 4.85 | |

| FAVCV/DF/16/DU | 1″ | 6000 | 82 | 45 | 8.30 | |

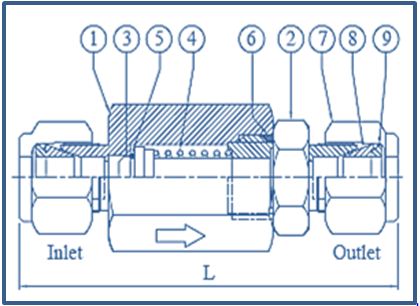

| Material Construction | ||

| # | Compon.n, | Material |

| 1. | Body | Duplex/ Super Duplex |

| 2. | Poppet | Duplex/ Super Duplex |

| 3. | Seat Seal | Viton |

| 4. | Spring | Duplex/ Super Duplex/Inconel |

| 5. | Spring Guide | Duplex/ Super Duplex |

| 6. | Stopper | Duplex/ Super Duplex |

| 7. | Joint Seal | Viton |

| 8. | Adaptor | Duplex/ Super Duplex |

Some Common Sizes for Duplex & Super Duplex Check Valve Compression are

- FAV SD UNS 32750, Check Valve, 1/8” OD, 15000 Psi

- FAV Duplex 2205, Check Valve, 1/4” OD, 15000 Psi

- FAV SD 2507, Check Valve, 3/8” OD, 15000 Psi

- FAV Duplex UNS S31803, Check Valve, 1/2” OD, 15000 Psi

- FAV Duplex 2205, Check Valve, 3/4” OD, 15000 Psi

- FAV SD 2507, Check Valve, 1” OD, 15000 Psi