Tube inserts and Tube ferrules are a metal inserted into the end of a heat exchanger tube to provide protection to the Tube mouth ends of a shell & tube type heat exchanger. The need for this Tube Ferrule arises as all tube failures occur within the first few inches of the heat exchanger tube inlet-end. The solution to this situation is the use of a thin wall covering in form of metal tube insert expanded full length into the inlet-end of condensers and heat exchangers. FAV tube insert is designed to ensure a smooth and gentle transition of the fluid down the tube insert to the condenser or heat exchanger tube. We have Metal tube insert and Plastic/Delrin Tube Inserts.

Tubes Inserts and Ferrules

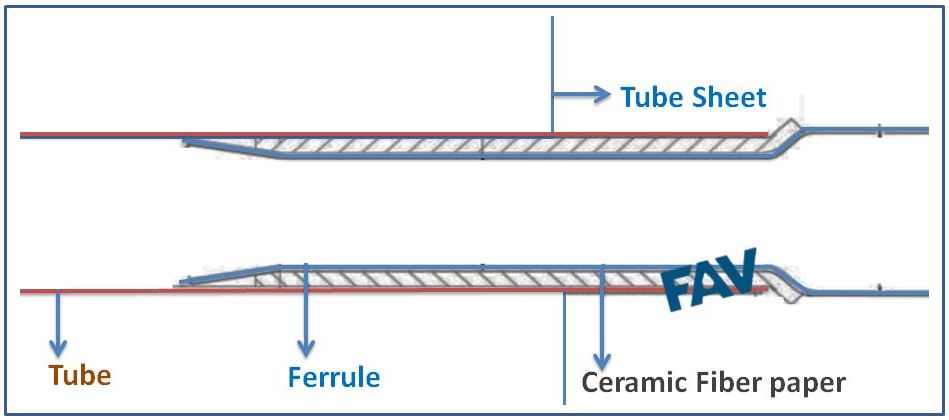

Heat Exchanger Ferrules arrangement

The purpose of the Tube Ferrule Inserts

1) Protect inlet-end erosion & corrosion

2) Act as a protective layer

3) Reduce the medium impact

4) Transfer extremely high heat past the tube sheet to the exchanger tubes.

Common problems at Shell & Tube Type Heat Exchangers

1. Tube-end erosion/corrosion

2. Stress Corrosion Cracking

3. Crevice corrosion

4. Localized pitting

5. Ammonia grooving

6. Improper tube expansion

7. Weakened tube-to-tube sheet joints

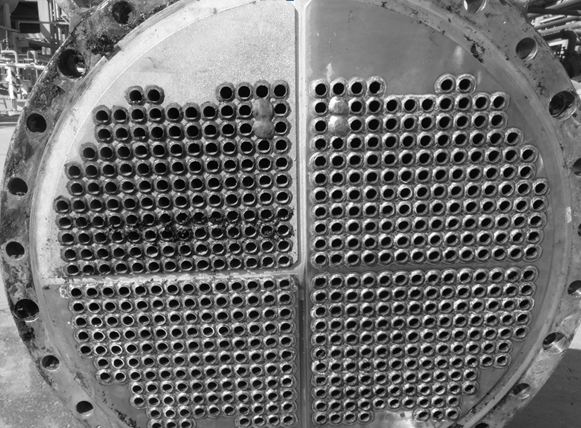

Installation Area for Tubes Inserts

Material of Construction for FAV Heat Exchanger Ferrules .

Plastics : Nylon ( Polyamide ), PTFE ( We have dedicated page on PTFE. CLICK HERE ), PP. Bakelite ( We have dedicated page on Bakelite. CLICK HERE)

Metal tube inserts in SS 304 /310/316/ 317 /321/347/ 410 / duplex, Hastalloy, Cu-Ni 90/10,Cu-Ni 70/30, Titanium, Aluminium Brass, Aluminium Bronze , Carbon Steel(B) Hastelloy C 276 , Monel 400, Monel 500, Duplex, Super Duplex ,

Where and why Fiber Paper is used ?

Ceramic fiber papers are used in most cases but they may not be a necessity in the Set-up. Ceramic fiber papers are used to cover the Ferrules before being inserted inside the Tube Mouth . They cover the space between the tube and the Ferrules .Ceramic fiber papers offer many unique problem-solving advantages like High-temperature stability, Low thermal conductivity, Low heat storage,Weight reduction, Resiliency,Thermal shock resistance, High heat reflectance, Easy to wrap, shape, or cut…etc

Fiber Ceramic Paper for Tubes Inserts

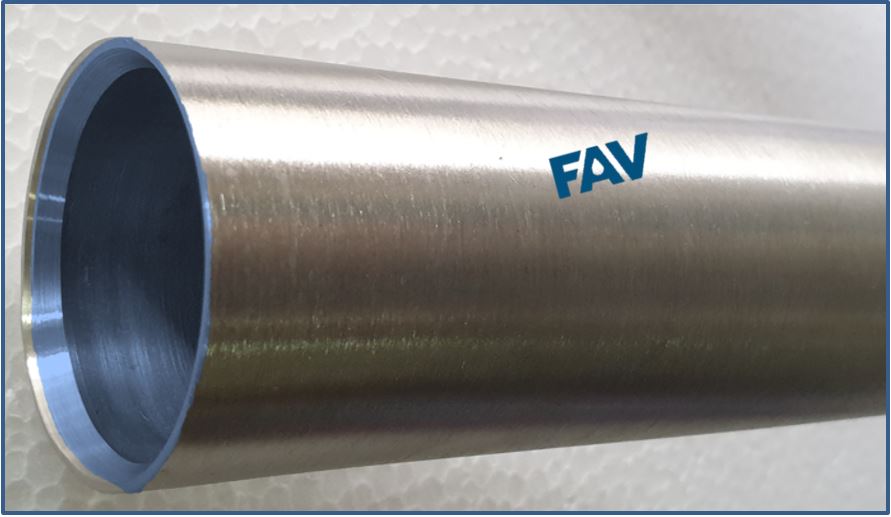

Heat Exchanger Ferrules from Pipe

This is the most efficient and economical method. If required then Flaring and inner cuts are achieved through machining. Die Press may be used to get the right shape .Only drawback is that the Pipes may not be available for all the sizes and grades

Heat Exchanger Ferrules from Solid Round Bar

Through this method the Ferrules are machined from Solid round Bar . The level of accuracy and precision is highest through this method .It is ideal when the sizes are small or quantity is less as machining from Solid Bar is expensive process. This is also used when the Raw Material is either Nylon ,PP ,PTFE or Bakelite .

Heat Exchanger Ferrules from Welded Pipe

By this method Plates are made in Pipe form by Welding . Further machining is done depending on design and drawing .This method is last resort when above two are not possible .

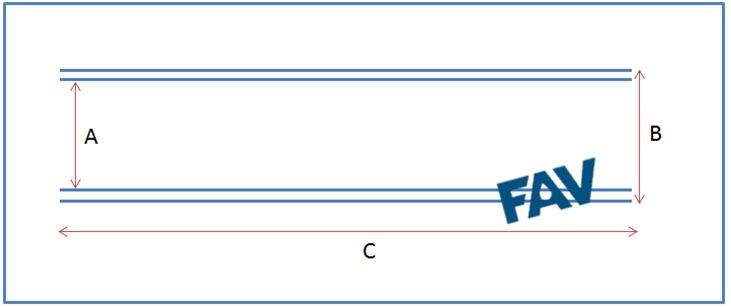

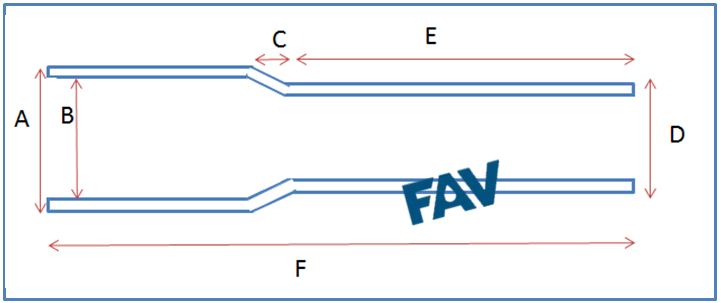

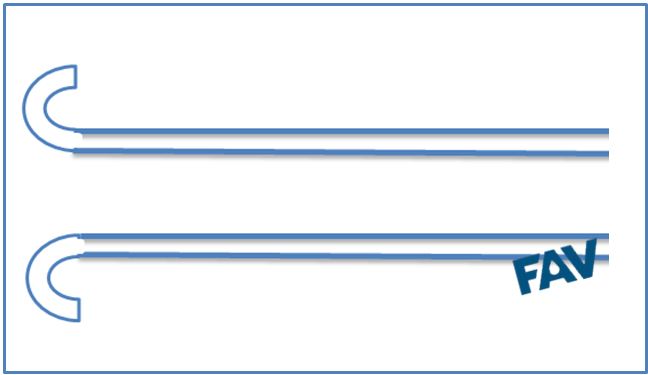

Straight Tube Ferrule Insert

These are the basic form of Tube Ferrules . Very economical and serves the basic purpose of Tube Mouth Protection . Ideal when there is not enough space at Tube Mouth for Ferrule Flares.

Bar Stock Ferrule Insert

These are machined from Solid Round Bar . Expensive as lot of material is wasted in manufacturing. Useful for small sizes and where precision is of utmost important. Commonly used when the material is PP ,Plastic, Nylon ,PTFE Teflon or Bakelite . Is used in metal when Pipes are not available for Construction.

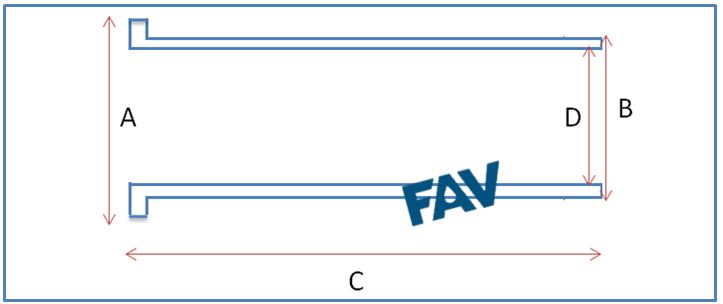

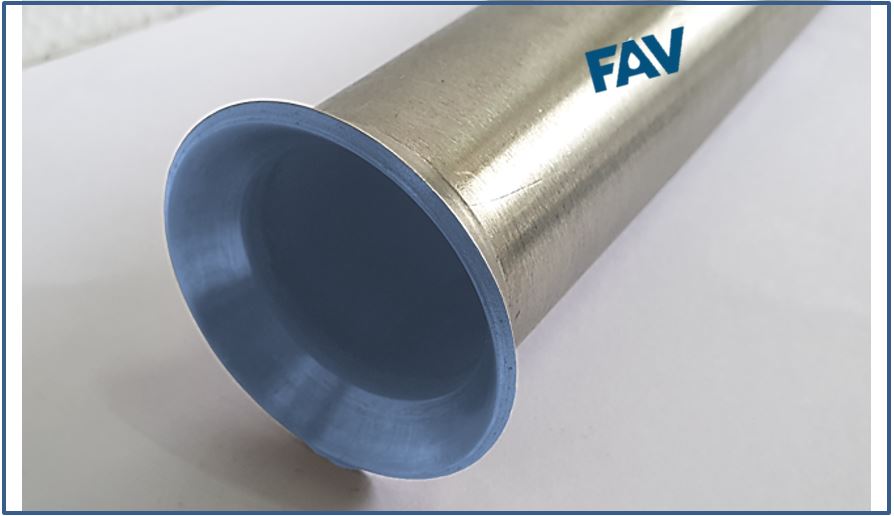

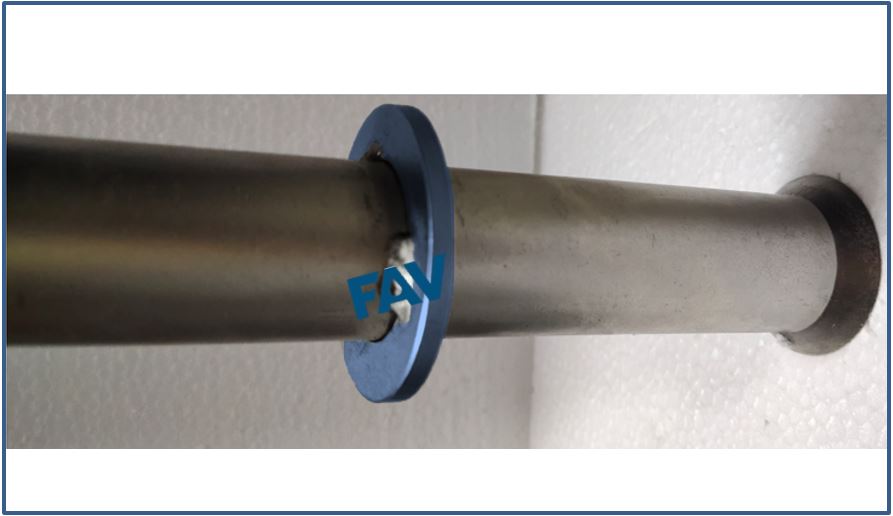

Standard Flare Ferrule Insert

With Single Flare on the outer side this the most commonly used and widely accepted Ferrule Inserts. Flaring serves the purpose of holding the Ferrule Inserts with Tubes . Also does not necessarily require use of Ceramic Fiber Paper.

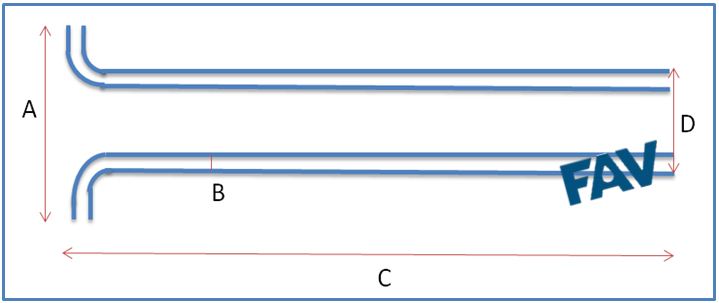

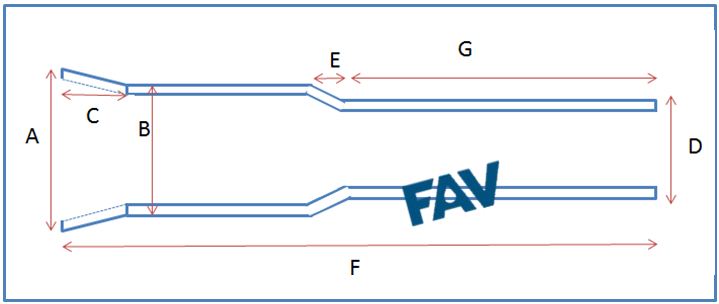

Single Flare with Back cut Tube Insert

A variation in above design having degree at the tail. Helps in easier installation where there may be hindrance/aberration in the tubes.

Single Flare Long Tube Insert

With Extra Length after Flaring this Tube Insert is useful when used with Ceramic Fiber Paper. Sometimes these are hammered inside the Tube for proper fit.

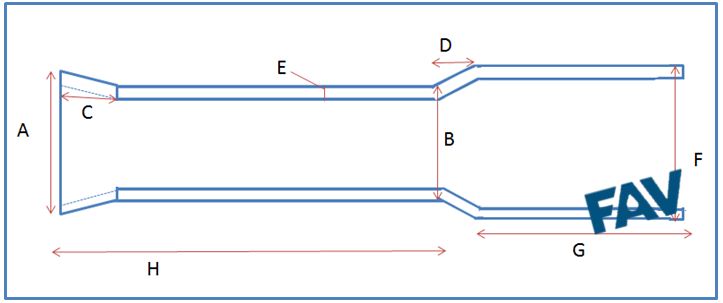

Double Flare Stepped Tube Insert

With Double Flaring this Tube Insert is useful when used with Ceramic Fiber Paper.

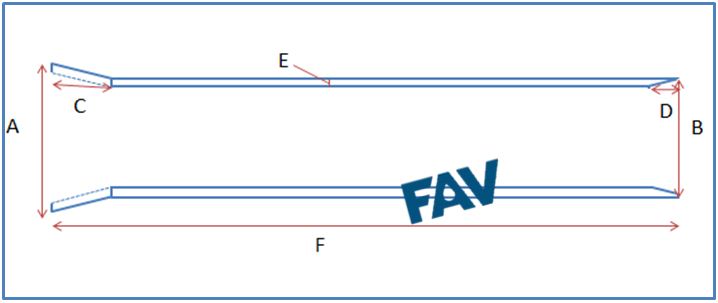

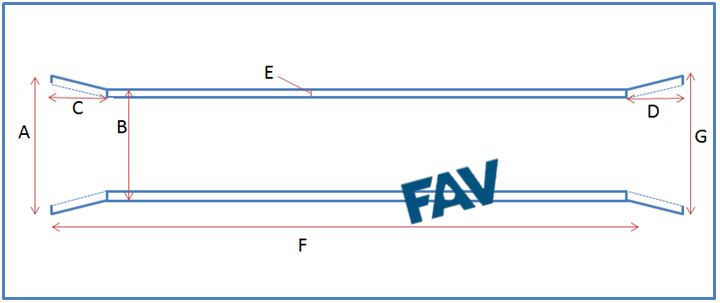

Double End Flare Tube Insert

This has Flaring at both Start and End . Degree may defer at both ends to ensure correct installation .

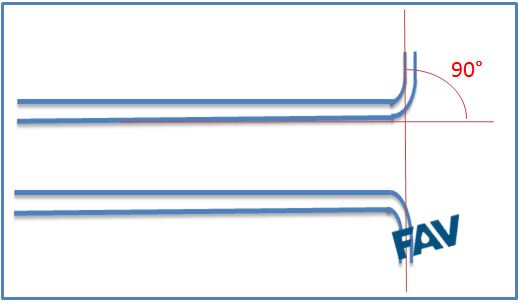

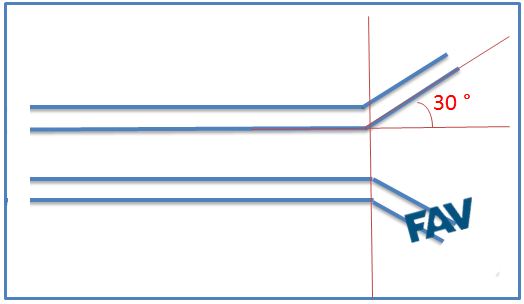

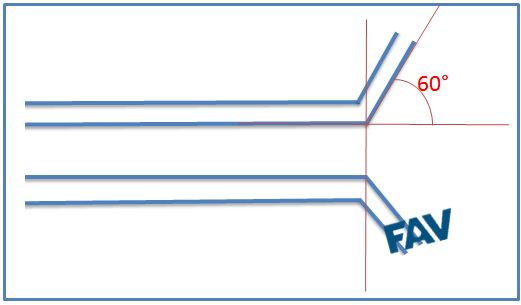

Degree or Reverse Flaring at Back End of Ferrules

FAV Ferrules gives you option at the back end of a 30 Degree to 60 Degree machining at the end . We have capability of machining them on Ultra long Ferrule Inserts also

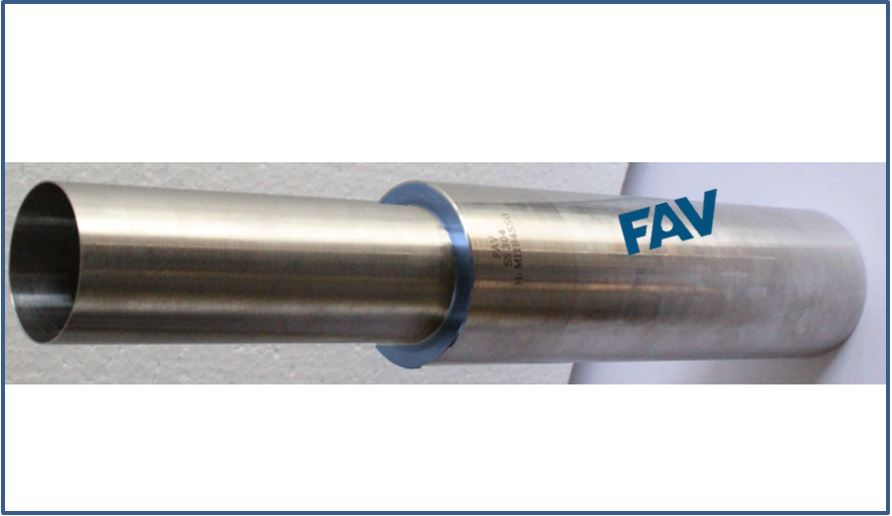

Heat Number Traceability

All Ferrules comes with complete Heat Number Traceability and standard marking

Range of Flaring Options at Front End of Ferrules

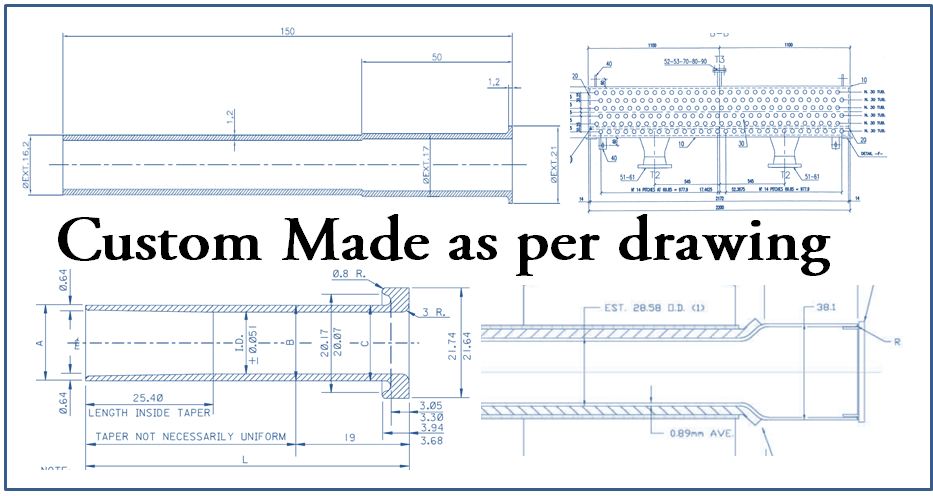

With FAV Ferrules you can design your Flaring OD, Degree and Taper as per the needs of your Tubes

Stepped Options

For Solid Bar Ferrules we can machine to Give you reduced ferrules after certain length .

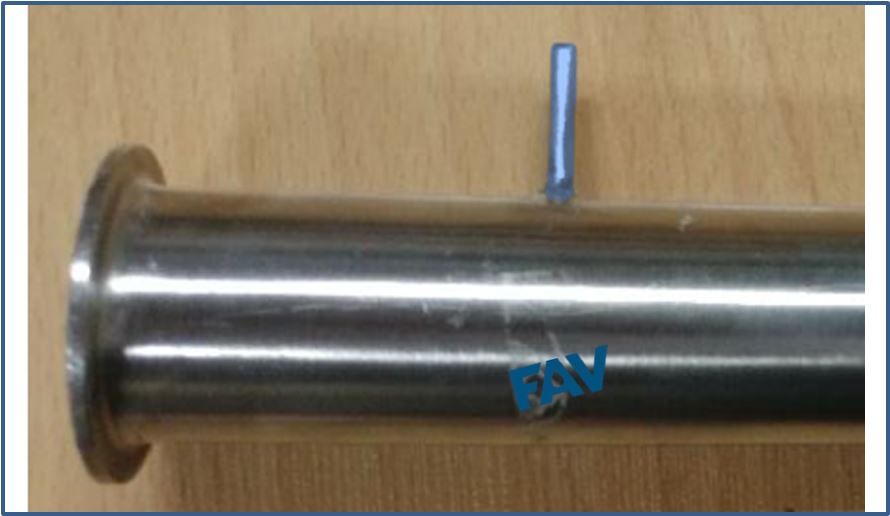

Support Pins

We can give Multiple Pins welded on the ferrule at various ends . Just send us the drawing and we will do it .

Support Clamps

We can give Support clamps which will be tack welded on the ferrule at various ends . Just send us the drawing and we will do it .