Hastelloy C276 Fittings And Hastelloy C276 Valves

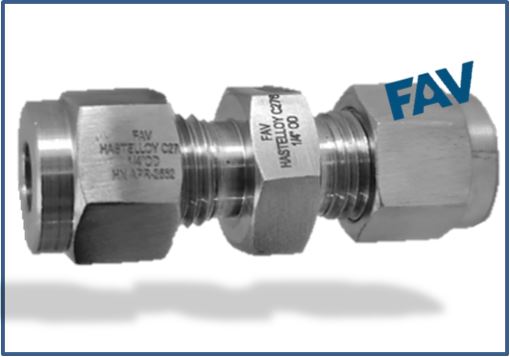

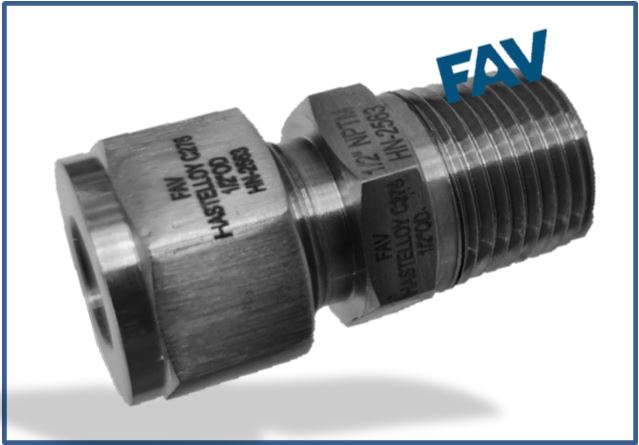

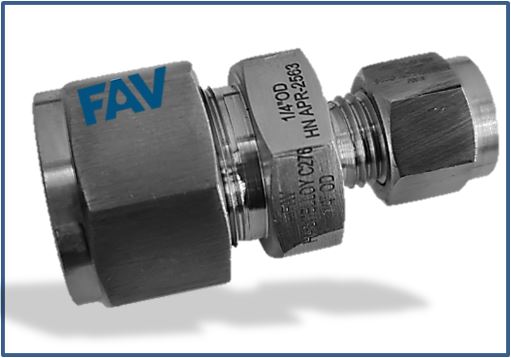

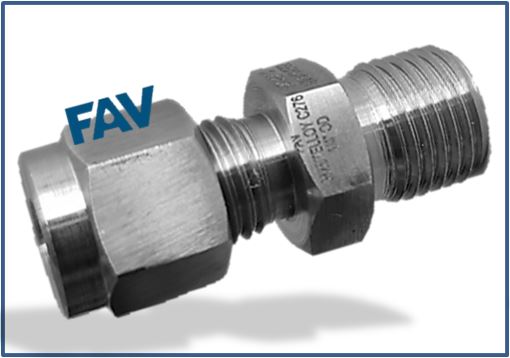

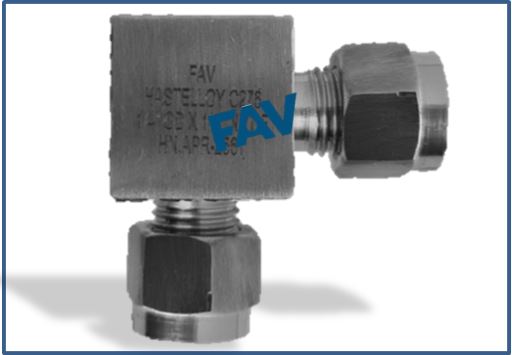

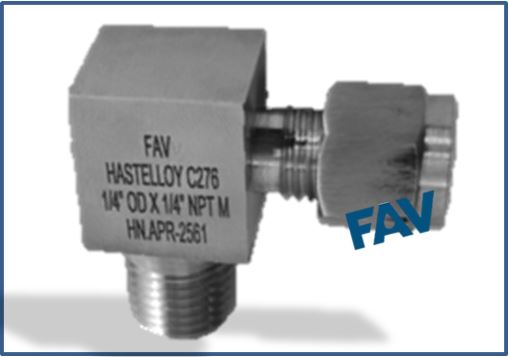

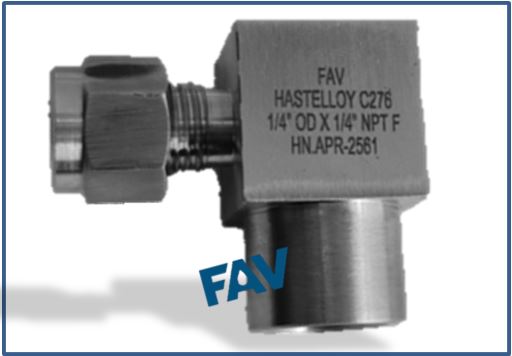

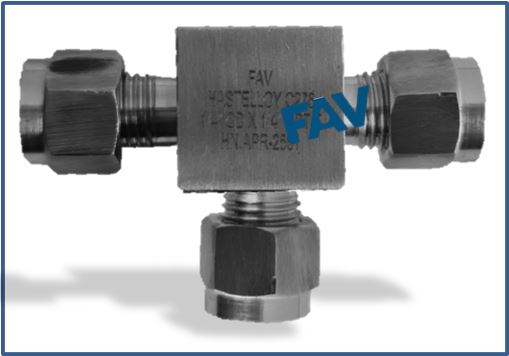

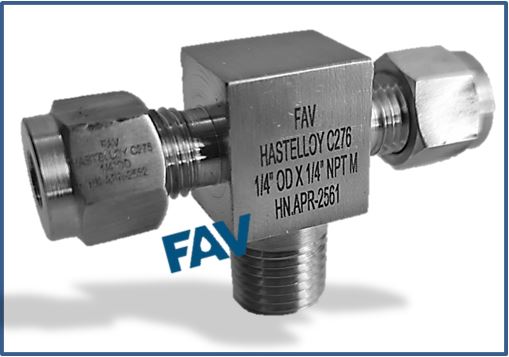

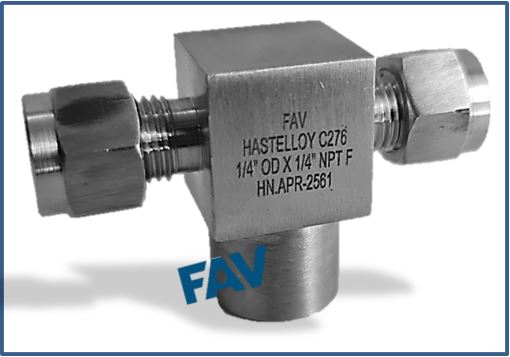

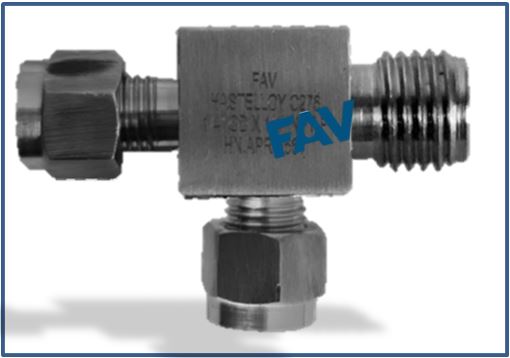

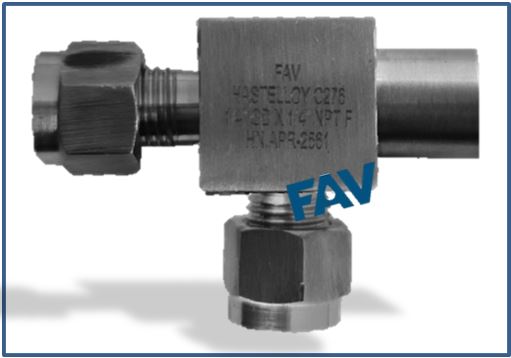

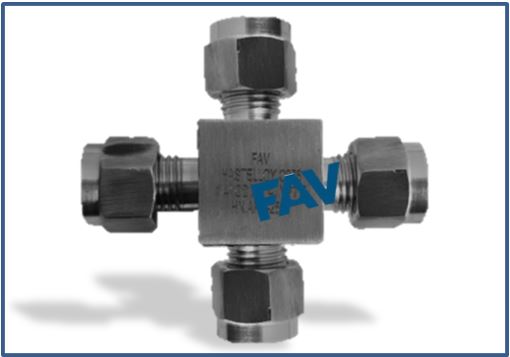

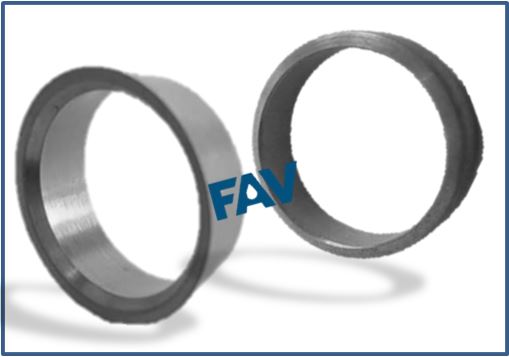

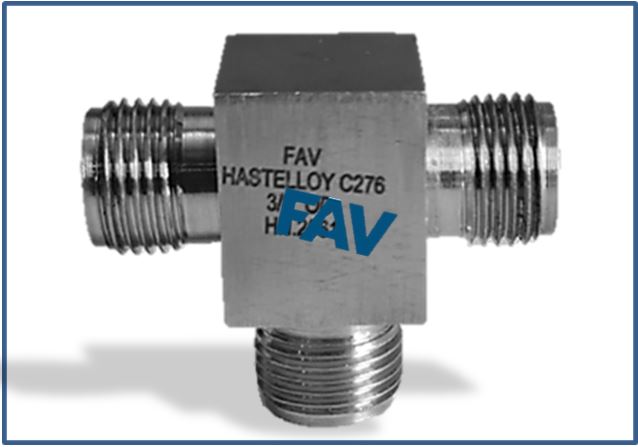

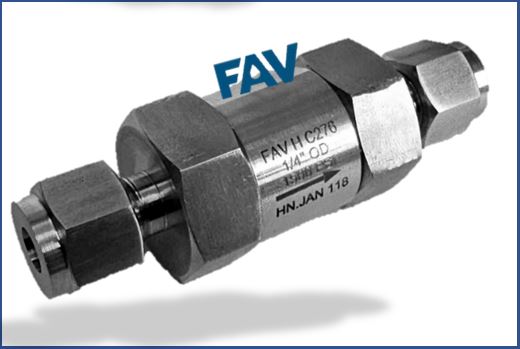

Manufacturer of Hastelloy C276 Double Ferrule Compression Tube Fittings which includes Hastelloy C276 Union, Hastelloy C276 Reducing Union, Hastelloy C276 Male Connector, Hastelloy C276 Union Elbow, Hastelloy C276 Elbow Male x OD, Hastelloy C276 Elbow Female x OD, Hastelloy C276 Union Tee, Hastelloy C276 Branch Male Tee, Hastelloy C276 Branch Female Tee, Hastelloy C276 Male Run Tee, Hastelloy C276 Female Run Tee, Hastelloy C276 Union Cross, Hastelloy C276 Tub Cap, Hastelloy C276 Nut, Hastelloy C276 Double Ferrule Front & Back.

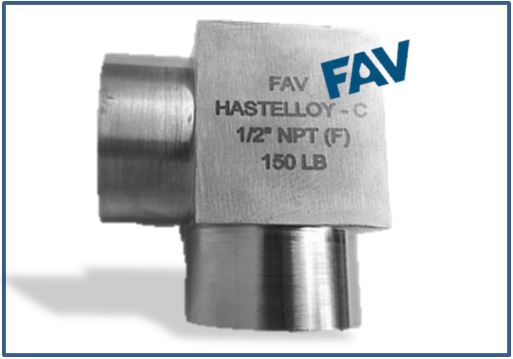

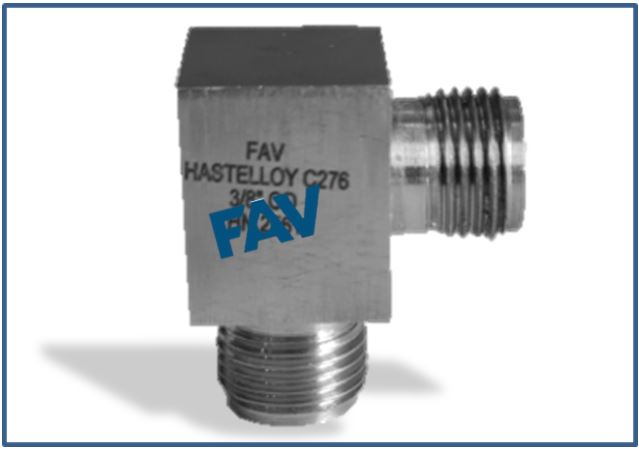

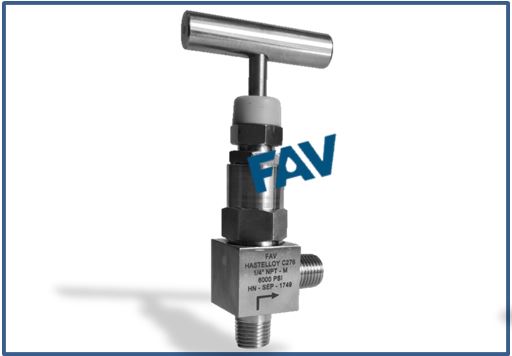

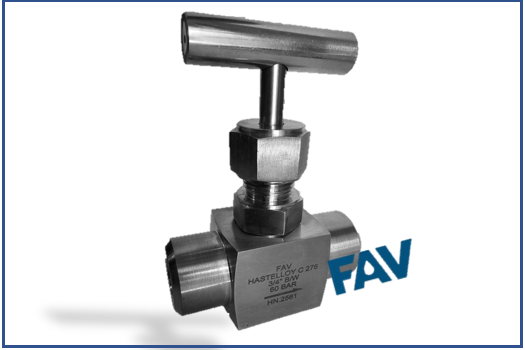

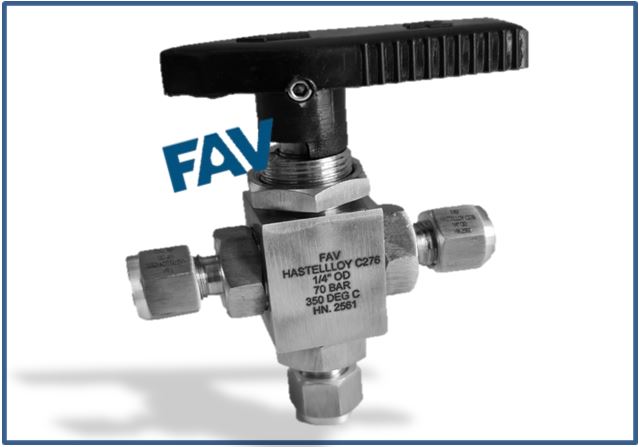

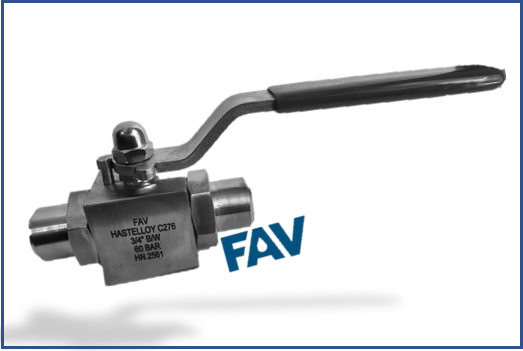

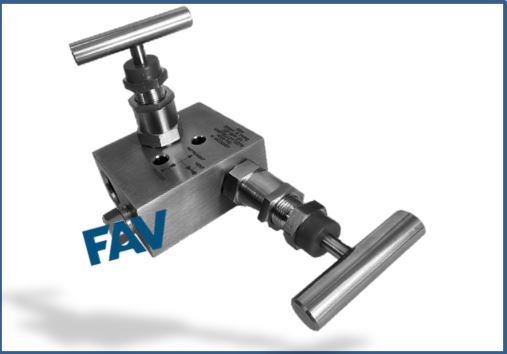

We also manufacture Hastelloy C276 Pipe Fittings and Hastelloy C276 Valves which includes Hastelloy C276 Elbow, Hastelloy C276 Tee, Hastelloy C276 Cross, Hastelloy C276 Plug, Hastelloy C276 Angle Needle Valve Male, Hastelloy C276 Sampling Cylinder, Hastelloy C276 Thermowell, and Hastelloy C276 Flange.

Properties of Hastelloy C276 Fittings & Valves

Hastelloy C276 is a wrought corrosion-resistant alloy. A major advantage of this alloy is that it mostly does not require solution heat treatment after welding. It resists the formation of grain boundary precipitates that would degrade corrosion resistance.

Hastelloy C276 Fitting and Valve are well known for Good machinability, although the alloy work hardens as is true of the nickel base alloys in general. Can be cold worked by all conventional methods. Weldable by all common methods except that excessive heat input should be avoided.

Can be used in the “as-welded” condition without further heat treatment for most corrosive applications. The alloy can be forged or hot-upset by conventional means. Can be hot formed or extruded. Should be solution heat treated following hot forming.

Applications

Some of the area of present or potential use for alloy Hastelloy C276 are: Acetic acid/Acetic Anhydride, cellophane manufacturing, chlorine spargers, chlorination systems, circuit board etching equipment, complex acid/chemical mixtures, fans and blowers, galvanizing line equipment, gas scrubber systems, geothermal wells, HF furnaces, incineration systems, nuclear fuel reprocessing, pesticide production, phosphoric acid applications, pickling system components, plate heat exchangers, selective leaching systems, sulphur oxide cooling towers, sulfonating systems, and tubular heat exchangers

Advantages

Like other nickel alloys, it is ductile, easy to form and weld, and possesses exceptional resistance to stress corrosion cracking in chloride-bearing solutions (a form of degradation to which the austenitic stainless steels are prone).

With its high chromium and molybdenum contents, it is able to withstand both oxidizing and non-oxidizing acids, and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides. Furthermore, it is very resistant to sulfide stress cracking and stress corrosion cracking in sour, oilfield environments

Advantages of Hastelloy C276 Fitting

- Hastelloy C276 Fittings do not twist the tube during installation.

- Positive leak free seal assembly and reassembly

- Size range from 1/16” to 2” (2mm to 38mm OD tubing)

- Low torque Operation

- Make and remake of the fittings is very much eased, as nuts are silver plated internally to prevent galling of threads.

- Variety of end connections and patterns as per Customer Requests

We also have our range of Double Ferrule Fittings and Duplex Fittings.