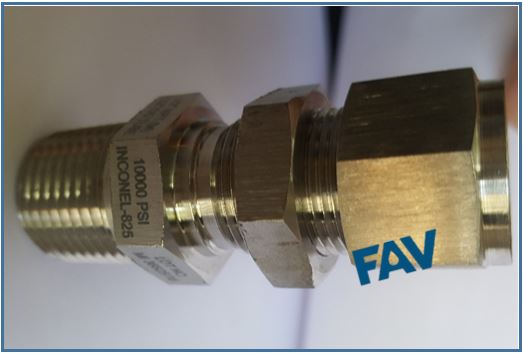

Inconel Fittings & Inconel Valves

FAV is the manufacturer of Inconel Fittings & Inconel Valves

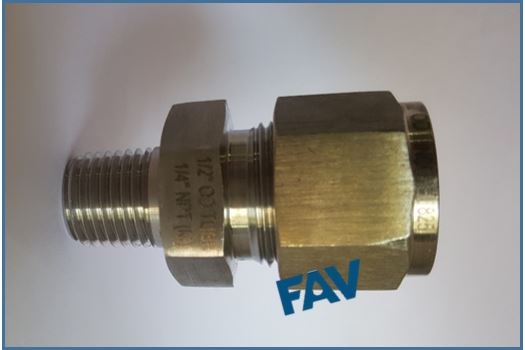

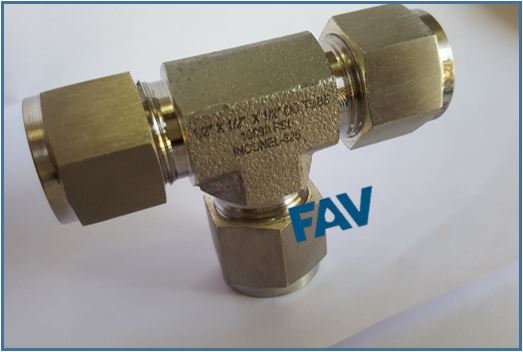

Main features that call for its use are its simplicity, compactness in design, ease of assembly, high reliability, easy availability & global acceptance.Various type of threads available like NPT (National Pipe Taper) and exceed the requirement of ANSI B1.20.1., BSP/ISO (British Standard Pipe/International Standard Organisation)., SAE/MS straight thread

Properties of Inconel Valves & Inconel Fittings

High tensile, creep, and rupture strength; outstanding fatigue and thermal-fatigue strength; oxidation resistance; and excellent weldability and brazeability are the properties of INCONEL alloy 625 that make it interesting to the aerospace field.

In brief Inconel Fittings & Valves has –

- Good resistance to acids, such as sulfuric, phosphoric, nitric, and hydrochloric

- Almost completely free from chloride induced stress corrosion cracking

- Excellent mechanical properties at both extremely low and extremely high temperatures

- Outstanding resistance to pitting, crevice corrosion and inter crystalline corrosion

- High resistance to oxidation at elevated temperatures

Applications

The properties of Inconel Fittings & Valves alloy 625 that make it an excellent choice for sea-water applications are freedom from local attack (pitting and crevice corrosion), high corrosion-fatigue strength, high tensile strength, and resistance to chloride-ion stress-corrosion cracking.

Industries in which Valves & Fittings are used?

- Chemical and petrochemical processing

- Components where exposure to high mechanical stress and sea water are required

- Flare stacks on offshore oil platforms

- Gas turbines, rocket motors/engines, and space craft

- Pollution control equipment

- Nuclear reactors

Advantages

- Variety of styles , shapes and sizes

- Sizes available from 1/8” to 2” NPT.

- Options of Precision thread end connections

- Very effective seal between pipes.

Inconel Needle Valve

Inconel Union Tee